Dynamic Designer Motion

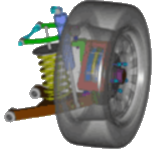

Motion Simulation embedded in Inventor

Simulate all aspects of mechanism motion.

Motion Professional is the complete virtual testing package for designers and engineer. Using animations and XY plots you will

size motors/actuators, determine power consumption, layout linkages, develop cams, understand gear drives, size springs/dampers, determine

how contacting parts behave, generate operating loads suitable for use by Finite Element Analysis, and much much more. Knowing this

information will help you answer two fundamental engineering questions: "Will it work?" and "Will it break?". If you

are a designer or engineer interested in understanding the performance aspects of your design before physical prototyping, you need Motion

Professional.

Motion Professional is the complete virtual testing package for designers and engineer. Using animations and XY plots you will

size motors/actuators, determine power consumption, layout linkages, develop cams, understand gear drives, size springs/dampers, determine

how contacting parts behave, generate operating loads suitable for use by Finite Element Analysis, and much much more. Knowing this

information will help you answer two fundamental engineering questions: "Will it work?" and "Will it break?". If you

are a designer or engineer interested in understanding the performance aspects of your design before physical prototyping, you need Motion

Professional.

How to use Dynamic Designer Motion Professional

Mechanism Animation

You will animate mechanisms based on the assembly constraints, any additional

constraints, and actuators you put in the model. A VCR-type interface

provides complete and intuitive animation control. Animations are

ideally suited to visualize the physical motion of your mechanism.

In addition to seeing the motion you can save it to an AVI

(movie) or a VRML (3D animated web format) file.

You will animate mechanisms based on the assembly constraints, any additional

constraints, and actuators you put in the model. A VCR-type interface

provides complete and intuitive animation control. Animations are

ideally suited to visualize the physical motion of your mechanism.

In addition to seeing the motion you can save it to an AVI

(movie) or a VRML (3D animated web format) file.

For more detailed motion analysis, you will visualize animations synchronized with XY plots of engineering data. You will use plots and mechanism motion together to identify possible system failure, part breakage, and safety issues.

Moving Interference Detection

Have you ever built a mechanism containing interfering parts? With Motion Professional you can eliminate interferences before you build the physical hardware. You will check for interferences between parts as the mechanism moves through the real operating range. In addition, you can tell the software to find the first occurrence of an interference or to calculate the minimum distance between parts. An intuitive interference browser lists all steps containing part interferences and selecting an interference highlights it in the model.

Engineering Data

You will use the engineering data available in Motion Professional

to really understand if your mechanism will work. Animations are

perfect for getting a basic understanding of the mechanism and communicating

that understanding to others. XY Plots are critical to gain intimate

knowledge of how the mechanism works. With Motion Professional

you can plot displacement, velocity, acceleration

and reaction load/moment engineering data. Presented in XY

plots, the raw engineering information is complimented with computed

information like power consumption, kinetic energy, potential energy,

and  momentum.

The XY plots will help you identify key events by allowing you to

overlay multiple values on a single plot and creating multiple plots.

For additional and customized data analysis, the underlying numerical

data can be exported to Excel.

momentum.

The XY plots will help you identify key events by allowing you to

overlay multiple values on a single plot and creating multiple plots.

For additional and customized data analysis, the underlying numerical

data can be exported to Excel.

Contacts

The motion of many mechanisms results from contacting parts. For example, consider a sprocket contacting a chain, a latch contacting a hook, a cam driving linkages, and backlashing gears. Simulating contacting parts is as simple as selecting the two (or more) contacting parts, specifying the associated materials, and running a simulation. The resulting output is accurate 3D motion and XY plots of the underlying information.

Dynamic Designer supports both 3D solid-to-solid and 2D curve-based contacts. The combination provides both power and efficiency. 3D contacts are the most general/powerful while 2D contacts are more efficient. Dynamic and static friction effects can be accounted for in both forms of contacts.

In addition to animation visualization tools, you can plot numerous useful engineering data including contact force and reaction loads. These data will help you quantify important design criteria like bearing loads and part size.

Cams and Gears

You will be able to understand complex cam and gear mechanisms using

Dynamic Designer Motion Professional. There are two ways

to incorporate cams and gears into your motion simulation: using

contacts or kinematic cam and gear elements. Contact

capabilities, discussed above, provide tremendous flexibility and

will help identify cam liftoff and gear backlash situations. The

kinematic cams and gears are very efficient, but will not show liftoff

and backlash conditions. Kinematic cams are simple to define using

either a point-to-curve or curve-to-curve. Kinematic gears are defined

by simply coupling the motion of one constraint/joint to the motion

of a second constraint/joint (e.g. one joint rotates 3 times for

every single rotation of a second joint).

You will be able to understand complex cam and gear mechanisms using

Dynamic Designer Motion Professional. There are two ways

to incorporate cams and gears into your motion simulation: using

contacts or kinematic cam and gear elements. Contact

capabilities, discussed above, provide tremendous flexibility and

will help identify cam liftoff and gear backlash situations. The

kinematic cams and gears are very efficient, but will not show liftoff

and backlash conditions. Kinematic cams are simple to define using

either a point-to-curve or curve-to-curve. Kinematic gears are defined

by simply coupling the motion of one constraint/joint to the motion

of a second constraint/joint (e.g. one joint rotates 3 times for

every single rotation of a second joint).

Dynamic Designer outputs valuable data to help you understand if your cam-driven and gear-driven mechanisms will work including animations, displacements, velocities, accelerations, and forces. You will use this information to size actuator systems, assess cam liftoff situations, limit gear backlash, and reduce part stress/strain.

Constraints/Joints

Mechanisms have parts connected, or constrained, together and move according to the connections. For example, a pendulum can rotate in a single plane relative to the part to which it is connected. Motion Professional offers a comprehensive list of constraints (or joints) to connect parts together. Examples include hinge (revolute), slider (translational), universal, ball (spherical) joints, and many more. Joint friction is available for each joint so that you can accuractely model the physical reality.

Force Driven Motion

Forces are constantly acting on the mechanisms you build. Motors apply a torque to drive a mechanism. Friction effects the actuator size required to drive your mechanism. Nonlinear springs load mechanisms. Dampers stabilize spring loaded parts. Motion Professional helps you build these forces, and many other, into your virtual prototype. Including these forces allows you to accurately model the physics of the mechanism.

Loads for Finite Element Analysis

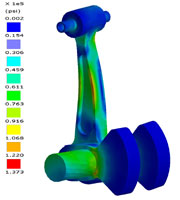

If

you use Finite Element Analysis (FEA) applications to answer the

"Does it break" question by analyzing parts or assemblies

that move, Motion Professional can provide information that can

substantially increase the accuracy of your analyses. As

parts or assemblies move, it becomes very difficult to know what

loads to add to your FEA model, and in what position the worst case

loading conditions occur. Motion Professional calculates accurate

loading conditions, including inertia effects, and can help

you determine where the maximum stresses will occur. Motion Professional

supports direct interfaces to leading Inventor based FEA products

such as DesignSpace.

If

you use Finite Element Analysis (FEA) applications to answer the

"Does it break" question by analyzing parts or assemblies

that move, Motion Professional can provide information that can

substantially increase the accuracy of your analyses. As

parts or assemblies move, it becomes very difficult to know what

loads to add to your FEA model, and in what position the worst case

loading conditions occur. Motion Professional calculates accurate

loading conditions, including inertia effects, and can help

you determine where the maximum stresses will occur. Motion Professional

supports direct interfaces to leading Inventor based FEA products

such as DesignSpace.

Interfaces

Motion Professional opens to door of communications with complementary packages including popular FEA packages (DesignSpace) and high-end ADAMS virtual prototyping solutions.

Motion Builder

Motion Builder technology helps automate the motion simulation

process making it available to even the most causal user. The Intellimotion

builder is a wizard that helps you quickly build motion models.

It logically takes you through each step, asking key questions and

gathering information as it generates the motion model. The resulting

model is ready to put into motion and see the results.

Motion Builder technology helps automate the motion simulation

process making it available to even the most causal user. The Intellimotion

builder is a wizard that helps you quickly build motion models.

It logically takes you through each step, asking key questions and

gathering information as it generates the motion model. The resulting

model is ready to put into motion and see the results.

Motion Browser

Motion Browser technology helps automate the motion simulation process making it available to even the most causal user. There are two ways to interact with Dynamic Designer Products: through a pull down menu and through the Intellimotion browser. The browser is a seamless extension of CAD tree tools. All Dynamic Designer functionality is available through the tree browser including motion model construction, simulation, and result viewing.

Quote

Quote Evaluation

Evaluation