Working Model 2D

2D Dynamic Motion Simulation

Plasma-Therm Optimizes a new Product Using Kinematics/Dynamics Analysis

Designing a better automated manufacturing system

still means accounting for the inevitable need for human intervention,

if only on occasion, to maintain the system. Recently, Plasma-Therm, Inc.

of St. Petersburg, Florida, expanded its product line with a robotic batch

loading system for a plasma deposition and etching product called the

Versalok. Plasma-Therm machinery must perform its tasks in clean environments,

using vacuum chambers to bake silicon materials for flat panel displays,

read-write heads and other products.

Designing a better automated manufacturing system

still means accounting for the inevitable need for human intervention,

if only on occasion, to maintain the system. Recently, Plasma-Therm, Inc.

of St. Petersburg, Florida, expanded its product line with a robotic batch

loading system for a plasma deposition and etching product called the

Versalok. Plasma-Therm machinery must perform its tasks in clean environments,

using vacuum chambers to bake silicon materials for flat panel displays,

read-write heads and other products.

Access to the automated robot loader and plasma chamber combination was designed to be through a heavy, 25.5-inch-square lid that would maintain the vacuum seal. However, the lid, which weighed 110 pounds, had to be easy enough for one person to open while the robotic loader needed servicing. Plasma-Therm mandated that gas shocks be used instead of a servo motor lift mechanism to reduce the overall cost of the new Versalock production system. The challenge was, what size shock would be needed to make the lid easy to lift, yet be small enough to fit within tghe restricted confines of the product. Because the Versalock's robotic loading module had to interface with a vertical elevator holding the silicon products to be treated, there were a lot of constraints on the available locations for the shocks due to the cramped space.

Accesible to Engineers and Designers Alike.

Normally, a Plasma-Therm engineer with an extensive physics background would have to do a lot of trial and error, solving equations, to determine the necessary gas shock force to use and experiment with prototypes to determine where to place the shocks for maximum effectiveness. Instead, it took one designer with little physics background just three days to use a kinematics/dynamics analysis program to answer these questions and produce results. Jeff Barriault, a mechanical designer with Plasma-Therm, chose Working Model from Design Simulation Technologies to solve his design questions. Working Model is a motion simulation program that applies the laws of physics to CAD models. Armed with the software and some dimension constraints, Barriault proceeded to attack the problem.

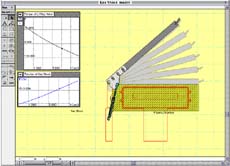

After sketching the basic chamber and lid configuration in AutoCAD, Barriault used dimensions from a manufacturer's catalog to insert a gas shock into his design. He then imported his preliminary AutoCAD layout drawing into Working Model via a DXF file.

Barriault then added some constraints to his model so the "virtual" shock would opperate just like a gas shock; e.g., the more the shock was compressed, the higher the pressure. "I entered a formula supplied by the manufacturer in one of the Working MOdel dialog boxes to create that effect, and then added other constraints to limit the extension and compression of the shock." Constraints are added neatly, with just a few mouse clicks, by using Working Model's pulldown menus and dialog boxes that prompt the user to enter either custom equations or select from default equations (based upon the dimensions and other parameters assigned to the masses in the model.)

Using a rope constraint and a separator constraint in the slot joint of the gas shock, Barriault selected "Run" to watch how forcefully the shock would open the lid when force was applied to the handle. He then performed more iterations, placing the shock in different locations, first locking down one end and then putting the other end at new position on the lid to see the change in force in force necessary to accomplish the same task of lifting the lid. (Barriault planned to use two shocks, but he only used one in the simulations and doubled the results.)

"At the pivot point, I put in a motor and moved it a constant velocity," explained Barriault. "When the lid was at a certain angle, I could see how much torque was required to keep it open because I had Working Model display a meter while the simulation was running to measure the force necessary." Barriault kept relocating the shock and running the simulation again until he found the optimum spot, which turned out to be a position where only seven pounds of force would be required to open the lid, and 10 pounds of force needed to close it. "That's not bad for a 110-pound lid," he added.

A fellow designer suggested that Barriault refine his test of the shock by simulated shock wear, to see how much force the shock would exert after six months of use. To make sure he had a ten percent margin of safety, Barriault re-entered the force equation in Working Model with a reduced force. Barriault ran the same simulation, using the optimum position of the shocks, but with 10 percent less forceto make sure the size of the shock and its location on the chamber would still be sufficient to raise and hold the lid in an open position. It did.

Verifying Results.

Had he tried to simulate all these tests on paper, he simply coudn't have, because of his own lack of training in physics. Barriault's supervisor, himself an engineer, was impressed by Barriault's ability to solve the design engineering task at hand using Working Model. The supervisor insisted on doing his own equations to double check Working Model's calculations and conclusions. They were the same.

"It would have taken a lot longer to get the Versalock design correct," according to Barriault, "probably weeks." Instead, Plasma-Therm's new Versalock is now in production after Barriault worked on the vacuum chamber lid problem for just a few days. Plasma-Therm plans to use Working Model to streamline, shorten, and lower the costs associates with similar design engineering tasks in future product launches.

Quote

Quote Evaluation

Evaluation